Support Cost: Selecting Cost-Effective Systems for Deep Foundations

Deep-foundation systems are expensive. Among multiple other design and decision parameters, cost-effectiveness should be considered when selecting among multiple viable foundation options. Wagner Komurka Geotechnical Group Inc. (WKG²) pioneered the concept of, and coined the term, “support cost,” which is an integral component of a rigorous, quantitative approach to selecting the most-cost-effective foundation system for a project. Throughout the two installments of our Support Cost blog series, we will explore this valuable decision-making tool.

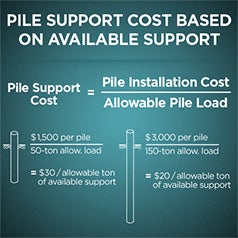

Sup•port’ Cost (sŭ•pōrt’ kŏst), n. The cost of an installed or constructed foundation element, component or system, divided either by its available, or its utilized, allowable load / factored resistance¹. Units are dollars per allowable ton, or dollars per structure design ton.

As a normalized parameter, support cost can be easily used to compare the relative cost-effectiveness of different foundation types (e.g., shallow vs. deep), different deep foundation types (e.g., drilled piers vs. driven piles), different driven pile types (e.g., H-piles vs. pipe piles), different pile sections (e.g., 10.75-inch vs. 12.75-inch-diameter pipe piles), different construction-control methods (e.g., wave equation analysis vs. load testing), different allowable pile loads and their associated depths (e.g., 75-ton piles vs. 150-ton piles), etc. The concept of support cost based on available allowable load is illustrated in the following figure:

A review of the figure indicates that the pile on the left has the lower pile support cost. However, this conclusion may be counterintuitive to some industry practitioners. It is often erroneously assumed that a pile that costs less per foot and is installed shallower, is more cost-effective than a pile that costs more per foot and is installed deeper. It is often also erroneously concluded that installing piles of the type on the right adversely affects productivity because fewer deeper, higher-capacity piles get installed in a day. However, productivity is properly determined based not on the number or piles installed, but instead on the number of tons of support installed.

WKG²’s cost studies have shown that piles with higher allowable loads tend to have lower pile support costs based on available support. Potential reasons for this include:

- Since piles are generally installed to transfer load through weak surficial soils to the more competent material below, a certain pile length is “invested” to penetrate the weak soils. The more available support that is provided relative to this invested pile length (and cost), the more-cost-effective the design becomes.

- Installed pile cost can be generalized as increasing linearly with depth; allowable load often increases at a faster-than-linear rate with respect to embedded length. So a given percent increase in embedded length may result in a greater percentage increase in allowable load, resulting in a more-cost-effective installation.

However, the concept of support cost based on available support is only half the story. Without an understanding of how support cost based on utilized support differs, the concepts presented above can be misapplied and lead to overly conservative and unnecessarily costly designs.

Check back for our Part II of our Support Cost series. For more information, visit wkg2.com for available webinars and technical papers, or email Van E. Komurka at komurka@wkg2.com.

Interested in learning more about driven piles? Click here to schedule a time to discuss the use of driven piles within deep-foundation systems with me.

¹For simplicity of presentation, allowable stress design (ASD) nomenclature will be used. The principles and concepts are also applicable to load and resistance factor design (LRFD).