HSS Showdown: ASTM A1085 vs ASTM A500

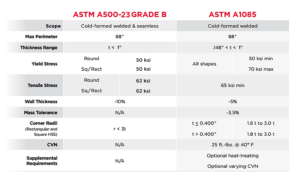

Although it’s been around for a couple years, there’s still a great deal of unfamiliarity surrounding the ASTM A1085 HSS spec. In an effort to continue to educate engineers about the applications and benefits of HSS (and that really is our mission at Atlas Tube), let’s compare a few of the properties that set ASTM A1085 apart from ASTM A500- 23 Grade B.

Yield Stress

ASTM A1085 has a single minimum yield stress of 50 ksi for all shapes of HSS (round, square and rectangular). This is the same minimum yield stress of most steel grades used in structural design, which makes it easy to remember. ASTM A500-23 Grade B has a 50 ksi minimum for round and 50 ksi for square and rectangular shapes.

The maximum yield stress of 70 ksi for A1085 HSS will lower the expected yield strength. This will lead to a reduced over-strength factor (Ry) which is used in the capacity design requirements for seismic design.

Material Tolerance

ASTM A1085 offers more stringent wall tolerances than ASTM A500-23 Grade B. This tighter tolerance limit along with the addition of a mass tolerance of -3.5% will allow the full nominal wall thickness to be used in the design of HSS. This means you’ll no longer have to reduce the nominal wall thickness by 0.93 (as prescribed in the AISC Steel Construction Manual) for member selection and connection design.

Charpy V-Notch Toughness

ASTM A1085 requires all HSS to meet a minimum CVN value of 25 ft.-lb. at 40° F. This is the CVN required by the AASHTO M270 (ASTM A709) for all Fracture Critical elements in service temperature Zone 2. Having this minimum CVN required makes HSS produced to this spec suitable for use in structures subject to fatigue, such as pedestrian and vehicular bridges. ASTM A500-23 Grade B does not have a minimum CVN requirement.

Want to know more about the A1085 spec? Download our product flyer and properties chart here.