Driven-Pile Economics – Support Cost Based on Available Support

As a continuing service to our clients, Atlas Tube routinely enlists the services of industry leaders in matters related to driven pipe piles. This is the second in a series of topics provided at our request by Wagner Komurka Geotechnical Group, Inc.

As discussed in Part I of our support cost series, support cost can be based on available allowable load, which can provide insights into the cost of installing allowable resistance to load (i.e., into the cost of supplying available support). However, the concept of support cost based on available support is only half the story. Without an understanding of how support cost based on utilized support differs, the concept can be misapplied and lead to overly conservative, and unnecessarily costly, designs. This post will discuss support cost based on utilized allowable load, which can provide insights into how efficiently installed resistance is utilized (i.e., what the demand is for the installed available support).

Pile support cost based on utilized support is a measure of the cost to use installed allowable support to resist load, and is defined as:

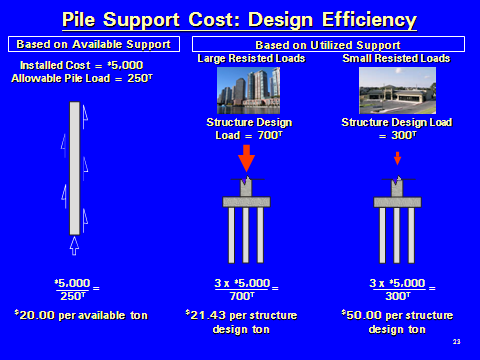

Pile support cost based on utilized support has units of dollars per structure design ton, and indicates how much the owner pays to use each ton of allowable support to resist load. When compared to pile support cost based on available support (how much the owner pays to install each ton of allowable support), it is an indication of how well allowable pile loads match actual assigned pile design loads (i.e., design efficiency). This concept is illustrated in the Figure 1:

(a) (b) (c)

(a) (b) (c)

Figure 1. Illustration of Design Efficiency Using Support Cost

Figure 1a illustrates a pile with a relatively high allowable load, and an installed support cost of $20.00 per available ton; the available resistance to support structure loads was installed, was put “in the bank” so to speak, is ready and waiting to loaded, at a cost of $20.00 per ton.

Figures 1b and 1c illustrate two potential design scenarios (each of which requires a minimum of three piles to satisfy structural stability). In Figure 1b, three of the 250-ton piles are installed to support a column with a design load of 700 tons, resulting in a utilized pile support cost of $21.43 per structure design ton (a relatively cost-efficient design). In Figure 1c, the same three piles are installed to support a column with a design load of only 300 tons, resulting in a utilized pile support cost of $50.00 per structure design ton (a relatively cost-inefficient design).

This example demonstrates that installing high-allowable-load piles, and then inefficiently loading them, is false economy. However, this conclusion may be counterintuitive to some industry practitioners, who subscribe to a “more allowable load is better” philosophy without appropriate economic assessment. The large disparity between the pile support costs based on utilized support presented in Figures 1b and 1c highlights the potentially significant effect on costs.

If you missed Part I of our Support Cost series, you can find the post here. For more information about deep foundations, visit wkg2.com for available webinars and technical papers, or email Van E. Komurka at komurka@wkg2.com.